Step1

Applicable raw material types

- 1. General plastics (PP, PE, PVC, ABS, PS, AS)

- 2. Engineering plastics (PA, PBT, PMMA, CA, PPS, POM, PC)

- 3. Various soft plastics (TPR, TPU, TPE, PVC)

Step2

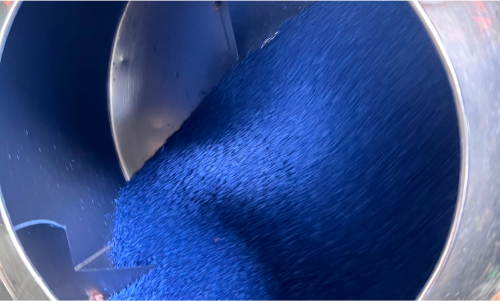

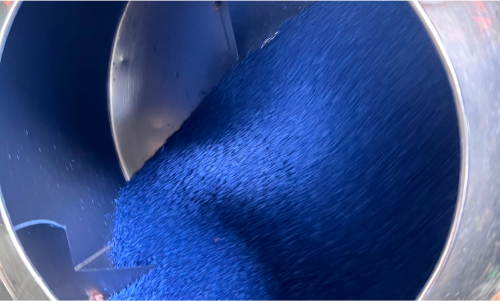

Baking/mixing ingredients

Most plastic raw materials will have trace amounts of moisture attached to the surface of the raw materials. When these trace amounts of moisture enter the high-temperature material tube, it may affect the "appearance" and "physical properties" of the product, and may also cause injection instability. situation, so most plastic raw materials need to go through a drying process before production. Different plastic raw materials have different water absorption rates. The difference in water absorption comes from the "polarity" of the raw materials. Plastics with high polarity have higher water absorption rates. Extremely high. On the contrary, plastics with low polarity are not easy to absorb water and do not even need baking materials.

Step3

Inject the product through the machine

After the prepared plastic raw materials are heated by the machine, the raw materials are sent to the mold for injection molding.